上海金畔生物代理MiTeGen品牌蛋白结晶试剂耗材工具等,我们将竭诚为您服务,欢迎访问MiTeGen官网或者咨询我们获取更多相关MiTeGen品牌产品信息。

Freeze Substitution Module

The EMS-002 Freeze substitution module is a simple cost-effective method to achieve freeze substitution. Once your samples are frozen on the EMS-002 Cryo Workstation the cryogen condensation module can be removed from the stainless steel Dewar and replaced with the substitution chamber. The freeze substitution controller will control the liquid nitrogen levels automatically as well as the substitution process itself. The user just has to monitor the systems progress during substitution and perform scheduled substitution media changes.

SKU: M-CEM-37465Category: Cryo-EM Instrumentation

Product Information

- Freeze Substitution

- Freeze Substitution Chamber

- Freeze Substitution Controller

在 1980 年代,描述性超微结构分析基本上走到了尽头,显微镜学家发现他们需要将结构与功能联系起来以推进他们的研究。大约在同一时间,生物化学家和分子生物学家能够看到分子与细胞膜相互作用的位置。通过在组织的抗原性中保留超微结构,将结构生物学家的工作与功能生物学家结合起来至关重要。在这项研究中,由于蛋白质的广泛重新分布、细胞质成分的提取和细胞抗原性的破坏,很早就确定使用化学品的常规固定方法不适合此类研究。

冷冻替代,即在低温下将冷冻水(冰)溶解在冷冻标本中,已被证明是电子显微镜中最强大的技术之一。样品中冰的溶解是通过用丙酮等无机溶剂分子代替水分子来实现的,同时用四氧化锇固定生物材料并用乙酸铀酰阻止染色。在缓慢升高的温度下,冰的这种缓慢溶解会持续数小时。替换过程完成后,可以用各种环氧树脂或丙烯酸树脂浸润和嵌入样品。甚至可以使用专用树脂在 -50° 摄氏度下进行低温嵌入。最终结果是保存完好的标本,既具有免疫定位研究的抗原性,又具有描述性超微结构分析的完美结构关系。

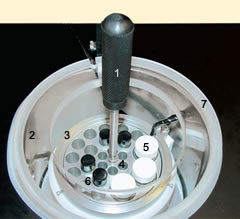

1. Transfer tool enables users move the substitution chamber in and out of the substitution chamber while at cryogenic temperatures.

2. Vacuum insulated stainless steel LN2 Dewar (Part of the Plunge Freezer)

3. Substitution chamber acts as the main heat sink and control interface for the substitution chamber.

4. Substitution holders large mass enhances temperature stability for the samples and media.

5. Substitution Media Vials Holders: Allows users to store extra substitution media at the correct process temperature for solution exchanges as required by the protocol being used.

6. Specimen Vials Holders: Containers for the tissue being substituted as well as the substitution media.

7. Substitution Chamber Lid: Helps maintain Dewar temperature stability and a pure Nitrogen gas atmosphere. Also excludes water vapor from the substitution chamber.

1. Programmable Substitution Temperature Controller: Comes preprogrammed from the factory to control precise ramp/soak times and temperatures critical to successful freeze substitution

2. Liquid Nitrogen Level Controller: Since the substitution process runs over the course of many days using published protocols, the LN2 controller insures that LN2 levels inside the Dewar are maintained at a level

appropriate for the process step being executed.